Turner Bellow’s custom Heart Monitor case is sold to various customers in the Medical Industry. This product consists of 5 parts sewn together using a Yamata single needle walking foot machine, a strip of bias added with a folding tool on a Consew single needle machine, and a belt clip inserted via a slot in the case.

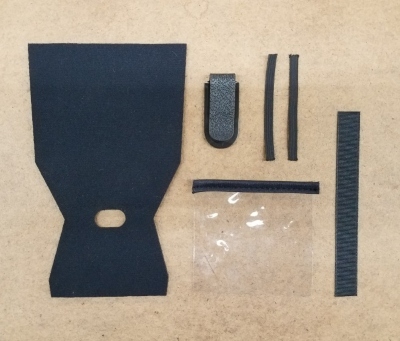

Parts are procured and inventoried by a Qualified Supply Base, and consist of Black 2.6mm SBR Neoprene, .012mm Clear Flexible Vinyl, Black Tex 80 Thread, ¼” Black Braided Elastic, Black Lycra Bias, 5/8” Black Cross Grain Polyester Ribbon, and a Belt Clip.

Die cut components include the Neoprene body of the case, and the vinyl viewing window. Strip cut components include the elastic loops for a lanyard attachment point, and a polyester ribbon which gives the case added strength.

This product went through various prototyping stages, and was tested with multiple materials before being sold to the customer. The end result is machine washable, durable, and easy to use. Orders of 200-400 pcs are ready to be shipped to Customer within 2 weeks.

Project Details:

- Product Name

Heart Monitor Case

- Project Scope

Made to Order, Minimum Order of 100 Pcs

- Capabilities Applied

Supply Chain Management, Prototyping, and Patterning

- Inspection Criteria

Heart Monitor (Functional Gage)

- Material Types

Black 2.6mil Neoprene, Black Tex 80 thread, Black ¼” Braided Elastic

Black Lycra Bias, 5/8” Black Cross Grain Polyester Ribbon, Clear Plastic Window, Plastic Belt Clip

- Product Specifications

Length: 5”

Width: 3.5”

- Color

Black

- Resistances

Water Resistant

- Special Features

Machine Washable, Charging Slot Included in Case, Two Carrying Options

- Operations Applied

Sewing, Mechanical Assembly, Die Cut

- Packaging

Standard Pack of 250 Pcs Per Box

- Design Work

Patterning, Prototyping

- Standards Met

IS0 9001:2015

- Drawing Type Accepted

All Common Formats

- Volume

100 Pcs Minimum Order

- Lead Time

2 Weeks Per 500 Pcs